ZetaOptimizer

Optimisation of sludge dewatering

by movement of charge on the surface of the sludge particles

• higher dm (dm: dry matter) content of the dewatered sludge

• significant reduction of polymer consumption

• higher separation efficiency of solids => considerable reduction of back-loading

Quelle: DWA Arbeitsgruppe KEK 2.6 „Neue Technologien zur Klärschlammbehandlung“

The dewatering of sewage sludge is one of the most important basic operations in the entire sewage sludge treatment process (Code of Practice DWA-M 366). With increasing obligations for thermal utilisation of dewatered sewage sludge depending on the quality of the sludge (Sewage Sludge Ordinance, Fertiliser Ordinance), the dm values (dm: dry matter) are becoming more important. For thermal utilisation, high dm values are required regardless of the process technology used (co-incineration, mono-incineration, pyrolysis). Higher dm values also have a positive effect on the reduction of transport costs, especially in the case of longer distances between the respective sludge dewatering and sewage sludge incineration/utilisation/disposal.

Various factors have to be taken into account for the water discharge of a sewage sludge to be dewatered, the effect of which cannot always be influenced. The force of the ζ-potential (zeta potential, electrokinetic potential) prevents wastewater constituents with a particle size of less than 20 μm from clumping together, so that they cannot be filtered with economic processes.

In the ZetaOptimizer high-voltage system, an electric field is generated by means of variably adjustable high voltage in the range between 0 and 80,000 V. The sludge to be dewatered flows through a flow reactor and experiences a movement of charge in the electric field. The interior of the flow reactor through which the sludge flows is free of installations. This prevents blockages and the formation of clogs. With a very low current strength of only max. 0.1 mA, the optimisation of sludge dewatering can be realised with only very low electrical power of max. 1 Wh / m3 (e.g. 20 Wh / 20 m3/h thin sludge) to be treated.

The strength of the electric field is adjusted individually to the sludge to be treated. Due to the different sludge properties, the curves of the dm value determined in each case in the dewatered sewage sludge are only very rarely the same, depending on the field strength set.

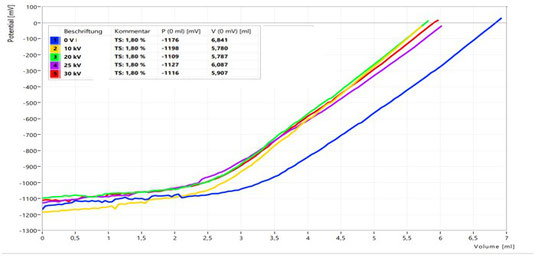

The movement of charge on the surface of the sludge particles occurs as a function of the strength of the electric field. The influence on the saving of polymeric flocculants (pfm) can be determined by streaming current potential measurement (charge titration with pFM).

In this example, almost all high-voltage settings lead to a lower consumption of pfm. In the diagram, the streaming current potential is shown above the consumption of pfm during charge titration. The blue curve describes the charge titration without the influence of the electric field (reference line at 0 volts).

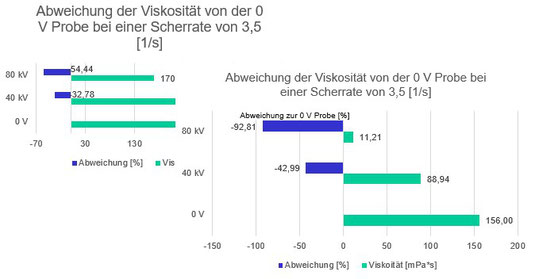

In addition to the consumption of pfm, the success of the movement of charge on reducing the viscosity can also be determined and represented metrologically. The viscosities at different electric field strengths compared to the untreated sludge sample (at 0 volts) were measured with a rheometer. A reduction in viscosity of up to almost 93% could be demonstrated.

Lower viscosity of the sludge to be dewatered favours the efficient mixing of polymeric flocculants.

For more information on the ZetaOptimizer high-voltage system, you are welcome to get a pdf file as an e-mail attachment. Please request it using the form below: